In order to help our customers reduce product costs and reduce their reliance on our company, we provide mold design and production services for customers, including plastic parts and stamping parts.

About mold design and production services

In general, if investors want to enter the mainstream market of their country and establish, cultivate or build their own brands, they will choose to invest in product molds for two reasons:

l The first, control costs.

l The second is to reduce the dependence on our company.

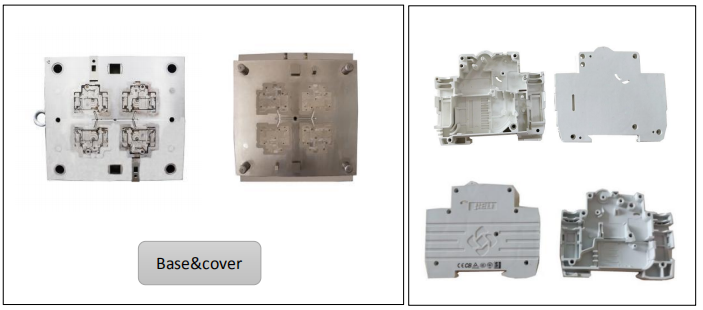

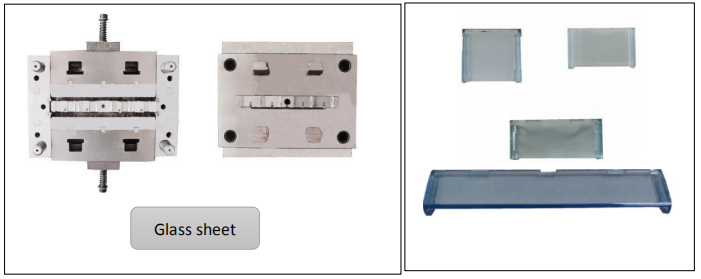

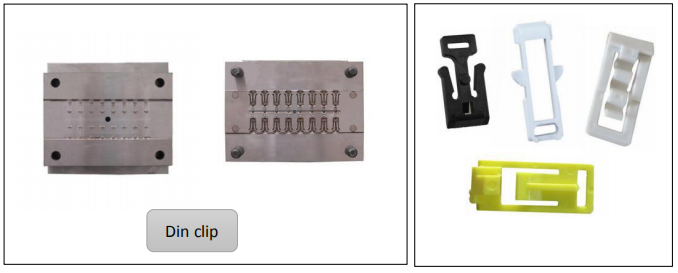

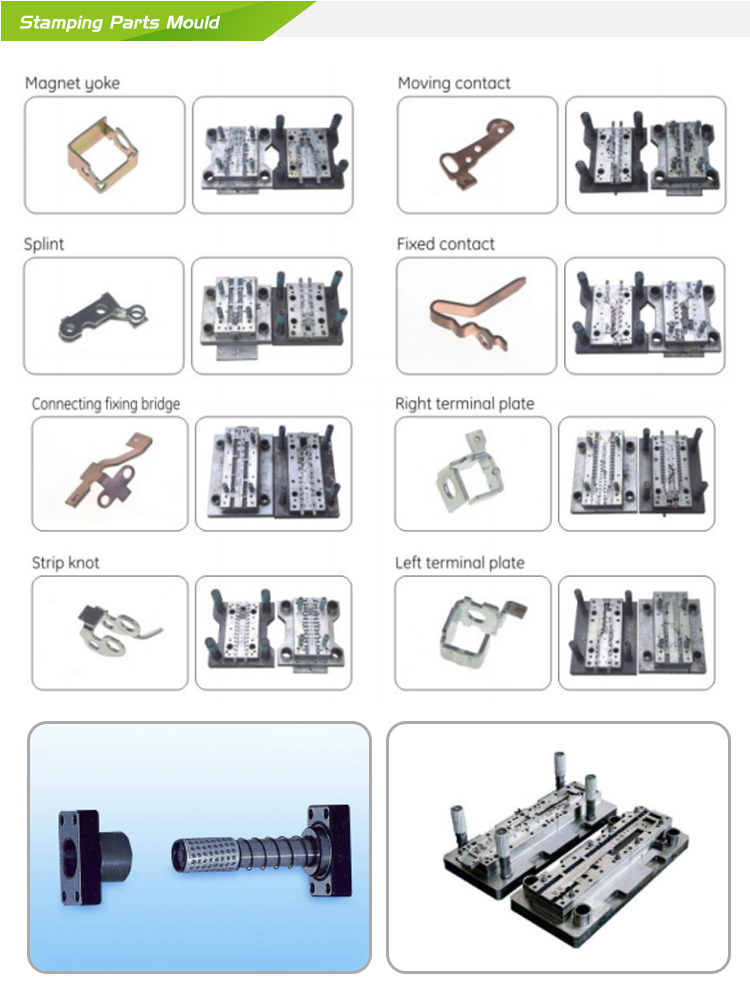

There are two main types of molds for MCB and RCCB. Our company provides design and production services for these two types of molds.

JIELI MCB & RCCB MOULD SERVICES

Application

·JIELI ELECTRICAL Provide design and manufacture services of stamping mould and plastic mould for MCB & RCCB products.

·Design and production of mould usually costs around 3-6 months.

Plastic Parts Mould

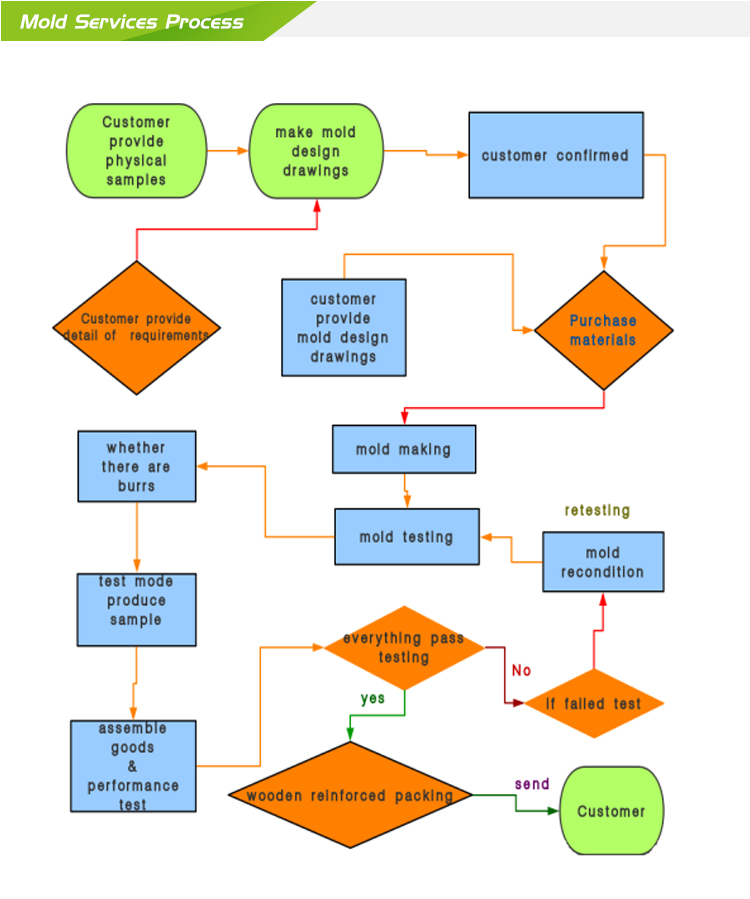

Mold development plan:

1. We can develop and produce according to the mold design drawings provided by customers.

2. We can design the mold drawing according to the physical samples provided by the customer, and develop and produce according to the design drawings after confirmation by the customer.

3. The customer puts forward the corresponding requirements of the product, we design the mold drawing according to the customer's requirements, and then develop and produce. (the mold must meet the customer's requirements for the product)

Mould Parameter values

1. Nylon PA66 25% glass reinforcement

2. Mould with : C45 MB RM

3. Mould inner parts: H13 or 8407 in SERTS RM Hardness 52-54 HRC .

All parts in China standards or According to customer requests.

20 years industry experience

JIELI ELECTRICAL focus on the field of low voltage circuit breakers for 20 years. Specializing in the MCB,RCCB and Safety switch products.

Professional mold design and production team

We have a team of professional mold design and production engineers, from design to material selection to production, the whole process of professional inspection and process to ensure the professionalism and precision of the mold.

The mold making cycle is short and meets customer customization.

Because we have a professional team, we ensure that our mold making cycle is about 3-6 months.

Improve professional mold verification process

After the other company's molds are completed, they are delivered directly to the customer after simple verification. But we are different, because we have 20 years of experience in the production of low-voltage circuit breakers, and we are very clear about the performance requirements of the mold. After all the molds have been produced, the molds must be handed over to the production team for repeated product production and product verification until the molds meet all performance requirements.

Good customer feedback, win-win cooperation

Up to now, we have provided molds for many products and construction services for customers in Iran, Egypt, India, Malaysia, Myanmar, Vietnam, Morocco, Turkey and other countries and regions.

Complete quality reflects product quality

Certification -We have passed ISO9001:2008 Quality Management System and CCC, CE

Packing & Delivery

PDF Download

PDF Download